Graphene-enhanced, low-carbon concrete successfully laid at Northumbrian Water site

A novel concrete formulation developed through collaboration between the Graphene Engineering Innovation Centre (GEIC) at the University of �������Ƶ, Cemex UK, Galliford Try, Sika and Northumbrian Water has been successfully laid on site, delivering a major milestone in efforts to decarbonise construction materials.

The project culminated in the successful pour of 15m³ of graphene and micronised lime-enhanced concrete at a Northumbrian Water wastewater treatment facility. This mix achieved up to 49% reduction in CO₂ emissions per cubic metre compared to traditional CEM I concrete, while maintaining comparable compressive strength performance.

From lab to site: delivering the CoMLaG system

The lower-carbon concrete, known as CoMLaG (Combining Micronised Limestone and Graphene), was developed and trialled at the GEIC and Cemex’s National Technical Centre. The mix uses a ternary cement blend, replacing a portion of the high-carbon clinker with GGBS and micronised limestone. To counter the strength losses typically associated with clinker reduction, a graphene-based addition formulated at GEIC was introduced to enhance strength development.

Following extensive lab trials, the project team scaled production through a batch plant in the North East of England using site-available aggregates and raw materials. The successful site application demonstrated the real-world viability of the mix and laid the foundation for future optimisation and deployment.

Monitoring strength in real time

The April 2025 slab pour was monitored using Cemex’s i-Con maturity monitoring system. The system provided real-time data on curing conditions and strength gain, helping validate the concrete’s performance under actual site conditions.

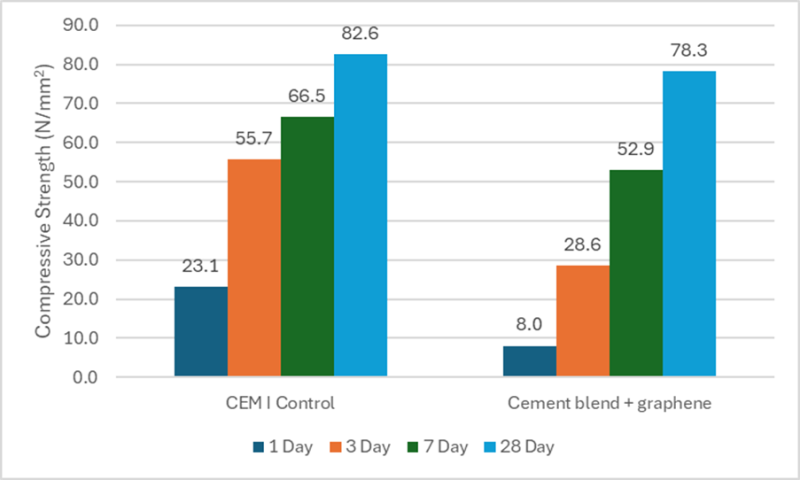

Slump and compressive strength tests showed results consistent with lab data. As shown in the graph below, the cement blend with graphene achieved a 28-day compressive strength of 78.3 N/mm², closely matching the 82.6 N/mm² of the CEM I control. While early-age strength values were lower due to reduced clinker content, the inclusion of graphene helped narrow the gap, demonstrating comparable performance to industry standards despite a significant reduction in CO₂ emissions.

Collaborative pathway to lower carbon concrete

This collaborative effort demonstrates the potential of advanced material science to support the construction sector’s net zero ambitions. The GEIC’s work to formulate and stabilise the graphene additive was central to ensuring performance at very low dosing levels (<0.1% by weight of cementitious content), while Cemex and Galliford Try enabled the transition from lab to large-scale pour.

“This project is a fantastic example of industry-led project with significant contributions from University of �������Ƶ research facilities to reduce carbon emissions in construction,” said Lisa Scullion, Application Manager at the GEIC. “Graphene-enhanced systems like CoMLaG open the door to concrete that performs well while significantly cutting its environmental impact.”

“At Cemex, we are committed to pioneering sustainable construction solutions, and this project exemplifies that mission,” said Mike Higgins, Director of Quality and Product Technology at Cemex. “The successful deployment of the CoMLaG project on a live site demonstrates how the use of advanced materials can help us reduce carbon emissions whilst remaining focussed on performance. Collaborating with partners like the GEIC, Galliford Try, and Northumbrian Water has been instrumental in accelerating the transition from lab innovation to real-world application.”

The next phase of work will focus on optimising the mix, improving admixture compatibility, and validating performance across a wider range of aggregates to support commercial rollout.

This successful collaboration between the GEIC, Cemex, Galliford Try, Sika and Northumbrian Water demonstrates how research and industry partnerships can drive meaningful progress in sustainable construction. Together, the partners are paving the way for lower-carbon concrete solutions that balance performance with environmental responsibility.